- Your cart is empty

- Continue shopping

In today’s fast-paced world, ready-to-cook meals are becoming increasingly essential. From working professionals to hotel kitchens, the demand for quick, convenient, and nutritious food is on the rise. One revolutionary solution helping both farmers and consumers alike is the food dehydration process.

India’s Food Wastage Crisis

According to the Food and Agriculture Organization (FAO):

- Nearly 40% of food produced in India is wasted every year due to poor infrastructure and the lack of cold storage.

- India wastes more fruits and vegetables than the entire UK consumes, and more grains than Australia produces.

The Horticulture Board also highlights:

- A 90% shortfall in cold storage capacity across India.

- Over 60% of existing cold storage facilities are concentrated in just four states: Gujarat, West Bengal, Uttar Pradesh, and Punjab.

The Impact on Farmers

Due to inadequate cold storage and refrigerated transport, farmers are often forced to sell their produce in nearby markets at unfair prices. In extreme cases, they have to throw away fresh fruits and vegetables because the cost of transport outweighs their selling price. This creates massive losses and discourages sustainable farming.

The Dehydration Solution

Food dehydration is a powerful method to extend shelf life and reduce food waste. It removes moisture from food items, allowing products to be stored for 1 to 5 years without refrigeration. For Indian farmers, this means:

- Higher value for their crops

- Less reliance on middlemen

- Ability to reach distant markets

What is the Dehydration Process?

The dehydration process involves removing water content from fruits, vegetables, and other foods through methods like:

- Hot air drying

- Spray drying

- Vacuum drying

- Freeze drying

These methods preserve the nutritional value, flavor, and color of the food, making them ideal for producing high-quality ready-to-cook mixes.

Ready-to-Cook Foods: Perfect for Modern Lifestyles

Dehydrated foods are a boon for today’s fast-paced life:

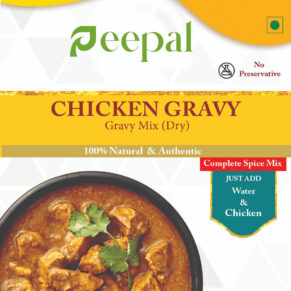

- Working professionals and working women with long commutes and busy schedules appreciate the convenience of instant Indian gravies like moong dal halwa mix, sambar mix, and dry gravy mixes such as those from Peepal. (Suppfarm Food Private Ltd)

- NRIs and people living abroad often find it difficult and expensive to access authentic Indian spices and ingredients. Dehydrated gravy mixes offer the taste of home without the hassle.

- Indian households benefit by cutting down on daily grocery trips and reducing food spoilage.

Dehydrated Foods in the HORECA Industry

The Hotel, Restaurant, and Catering (HORECA) sector faces a shortage of skilled kitchen staff, especially for tasks like cutting, peeling, and chopping. Ready-to-use dehydrated pastes like garlic paste, ginger paste, and onion paste reduce prep time and gas usage, which is becoming increasingly expensive.

Since many dehydrated ready-to-cook gravies do not require refrigeration, they help businesses cut down on electricity costs and simplify inventory management.

Benefits of Dehydrated Ready-to-Cook Products

- Extended shelf life (1–5 years)

- No refrigeration required

- Quick meal prep for busy households

- Reduced food waste

- Lower cooking costs

- Empowerment of farmers

- Support for restaurant owners and chefs

Conclusion: A Win-Win for All

The dehydration process is more than just a food preservation technique—it’s a transformative solution for India’s food supply chain. It boosts farmer incomes, supports urban consumers, and empowers the HORECA industry with efficient, cost-effective solutions.